Your work, the space available for the computer, the power supply you have, and the connection features you require all play a role in selecting the best industrial computer.

Performance

When it comes to an industrial PC, the central processing unit is the core, and it controls the total output of the system you pick. As a result, choosing a processor that can handle a wide range of workloads is critical.

To save money on the entire cost of an industrial computer, several people try to cut corners on the CPU. Sluggish performance, downtime, and productivity interruptions are all possible consequences of selecting a CPU with insufficient power. When selecting a processor to power your industrial PC, ensure that it is strong enough to maintain a continuous and uninterruptible operation.

In other words, buying a processor that exceeds your needs is a waste of money because you’ll be paying for power you won’t use. The expertise in assisting customers in selecting the best CPU solution for their workloads and dedicated apps is unmatched in today’s industry.

Premio offers a wide range of CPU alternatives for your industrial computers, from quad-core Intel® CeleronTM CPUs to Intel® 9th Generation Core® i7 Processors. Professionals in the business love Intel CPUs for their speed and dependability.

Interoperability

To properly design an industrial PC, you must first determine how much computing power you need, where your computer will be housed and how many apps you intend to run.

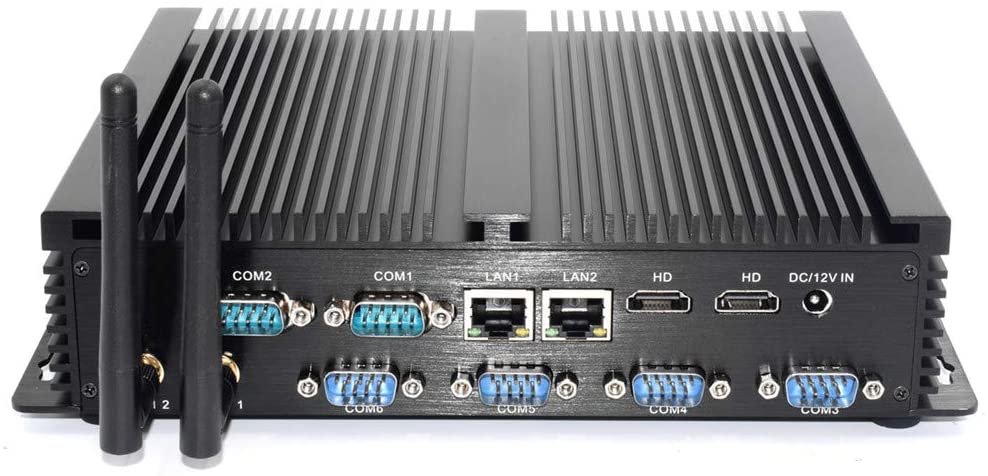

When configuring an industrial computer, you have the following connectivity choices: Ten gigabit Ethernet (GigE) LAN ports.

Serial ports may also be added to your industrial computer system if you have legacy technologies still being used today because of their durability and versatility.

Additional I/O ports may be added to your industrial computer system through modular daughterboards, which offer LAN RJ45/M12, serial connections, USB ports, DP ports and DIO port options.

One or more sensors or devices can be connected to an industrial computer through Bluetooth. Your system may be customised to meet your individual needs, regardless of the type of connectivity you want.

The Operating System

Many individuals don’t test the OS until they have the system in hand, although doing so is critical to ensuring the system’s smooth operation. Consequently, you work tirelessly with your customers to guarantee that their solutions perform correctly.

The ability to make a difference

Remote sites without reliable power are no match for rugged industrial computers. Industrial computers can run on DC power. To run on a vehicle’s 12/24VDC battery, specific industrial computers include the ability to switch between pc and car mode.

Expandable Storage, Memory, and Processors

When selecting an industrial PC, don’t forget to factor in the storage needs of your job. Standard HDDs and solid-state drives can be used in industrial computers (SSDs). If you want to execute non-real-time applications, a mechanical drive configuration can be used in your system.

However, if you need fast access to local storage, you should install an SSD on your computer. SSDs allow for real-time data processing and decision making because of their incredibly rapid data transmission speeds. In addition, because SSDs do not have moving platters that might be destroyed, they are more resistant to frequent shocks and vibrations than HDDs.

An M.2 NVMe Storage solution may be added to your system if you require the fastest available storage. NVMe discs connect NVMe discs directly to the PCIe interface, resulting in fast data transfer speeds. NVMe SSDs can write and read at 2,500 MB/s and 3,500 MB/s. Traditional SSDs and HDDs will always play a role in the storage architecture of some enterprises because of their large storage capacity.