Accurate flow measurement is crucial in various industries, including manufacturing, oil and gas, water treatment, and pharmaceuticals. It is essential for optimising processes, ensuring product quality, and maintaining safety standards. Tools that can aid industries in measuring the flow are digital panel meters. This article explores the benefits of achieving reliable and precise measurements.

Improved Process Efficiency

Accurate measurement enhances process efficiency by providing valuable data for optimisation. Industries can streamline operations and reduce waste by precisely measuring the rate of liquids, gases, or steam. It helps operators identify inefficiencies, optimise resource allocation, and eliminate bottlenecks in the production line.

For instance, mass meters measure the mass rate of a fluid directly. Equipped with digital panel meters, they provide real-time data on mass rates, allowing operators to make immediate adjustments. With the ability to monitor and control the flow precisely, industries can achieve optimal production rates, minimise energy consumption, and improve overall process efficiency.

Enhanced Product Quality

Precise measurement is essential for maintaining consistent product quality across various industries. In applications where precise ingredient proportions are critical, such as pharmaceutical manufacturing or food processing, it ensures that the right amount of each component is utilised. Deviations from the desired rates can indicate potential issues compromising product integrity.

For example, volumetric meters measure the volume of fluid passing through a system. These, when paired with panel meters, provide real-time volumetric data. By closely monitoring the flow rates, operators can ensure accurate dosing, precise mixing, and consistent product quality. The digital display allows for quick identification of any variations, enabling prompt corrective actions.

Effective Resource Management

Accurate measurement enables industries to optimise resource allocation and effectively manage costs. Companies can reduce waste and control expenses by accurately measuring the rates of raw materials, energy sources, or wastewater. It also facilitates accurate billing and allocation of resources among different departments or customers.

For instance, ultrasonic meters use sound waves to measure rates non-invasively, making them suitable for various applications. Equipped with digital ones, they provide real-time data. The display allows operators to monitor rates and quickly identify any abnormalities. It enables precise control over resource consumption, leading to optimised resource management and cost savings.

Safety and Compliance

Precise measurement is crucial for maintaining a safe working environment and ensuring compliance with industry regulations. Deviations from expected rates can indicate leaks, blockages, or system malfunctions that may compromise safety or violate regulatory requirements. It helps identify these issues early, allowing prompt action to mitigate risks.

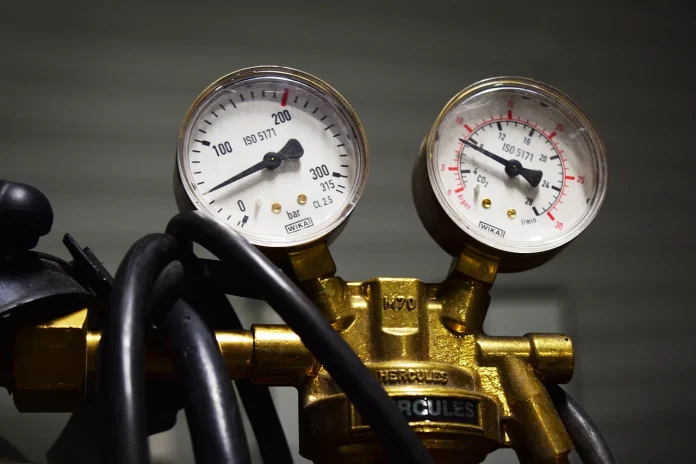

For instance, differential pressure meters measure rates based on the pressure drop across a constriction. Digital panel meters display real-time pressure differentials and flow rates, enabling operators to monitor conditions continuously. By closely observing these readings, industries can ensure safe operation, identify potential hazards, and take necessary precautions to maintain a secure working environment.

Process Control and Automation

Accurate measurement plays a vital role in process control and automation systems. Real-time data by panels allow for precise monitoring and control of industrial processes. By integrating measurement with control systems, industries can automate adjustments, ensuring optimal operation and reducing the need for manual intervention. It improves process stability, reduces human errors, and increases productivity.

For instance, magnetic meters utilise Faraday’s law of electromagnetic induction to measure the rate of conductive fluids accurately. Equipped with digital meters, they provide real-time flow data, allowing for seamless integration with process control systems. It enables automated adjustments based on flow readings, ensuring consistent and precise process control. If the fluid is insufficient, automated dispensing systems such as these will then transfer precise volumes of fluid.

Conclusion

Precise measurement is vital for industries across various sectors, offering numerous benefits, including improved process efficiency, enhanced product quality, effective resource management, and safety compliance. Digital panel meters integrated with different measurement technologies provide real-time data that enables precise control and decision-making. By investing in reliable measurement systems, industries can achieve higher efficiency, reduce costs, and maintain a competitive edge in today’s dynamic business landscape.