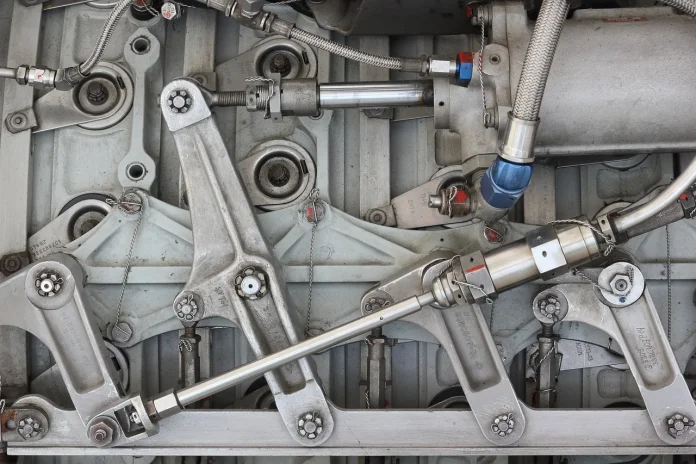

Hydraulic cylinders have a number of different uses, while this particular device is also known as a hydraulic ram and can be used in a variety of different mechanical situations. Hydraulic cylinders are usually comprised of a cylinder barrel that contains a piston which is connected to a piston rod. This particular part of the cylinder moves backwards and forwards depending on the pressure of the hydraulic fluid that is pumped into the cylinder to control the movement of the ram. The barrel of the cylinder is closed off by the cap end while the cylinder head is with a rock facing the cylinder. In addition, a number of important sliding rings and seals prevent the hydraulic fluid from leaking out of the cylinder maintaining pressure on the piston so that it can carry out its linear work and associated motion. If you are looking for a particular type of hydraulic cylinder to fulfil the role in your manufacturing facility or on a particularly heavy machine you could contact a specialist manufacturing company in Australia.

-

The main uses of hydraulic cylinders

hydraulic cylinders are generally used to lift lower objects that are particularly heavy, while hydraulic cylinder systems are often found on heavy machinery, including excavators and bulldozers. If you operate machinery, then you will be aware of the importance of maintaining hydraulic cylinders on your equipment to prevent leakages and subsequent pressure drops. A broken seal in a hydraulic cylinder could put a piece of heavy equipment out of work for a period of time until the seal is fixed. As a consequence, you must always undertake maintenance on your heavy equipment and if you require a particular type of cylinder to be created, you must contact a company providing hydraulic cylinder manufacturing in Australia.

-

Choose the right type of hydraulic cylinder

Furthermore, you may not be aware that hydraulic cylinders are available in a number of different styles, according to your requirements. Hydraulic cylinders can also be used for a number of different applications in factories and industrial facilities, along with heavy equipment. As a consequence, if you need a particular type of hydraulic cylinder, then you could think about talking to a specialist manufacturing company in Australia because they will be able to assist you.

-

Undertake regular maintenance

Finally, as previously stated, maintaining a hydraulic cylinder is essential to prevent pressure drops and leakages of hydraulic fluid. Moreover, if you want to make sure that the hydraulic cylinders in your factory or heavy equipment are working as intended at all times, you must schedule regular maintenance to prevent significant periods of downtime when machines need to be fixed.

- Take the time to learn about the main uses of hydraulic cylinders

- Choose the right type of hydraulic cylinder for your machinery or factory

- Undertake regular maintenance on hydraulic cylinders to prevent downtime

To conclude, if you want to learn more about hydraulic cylinders, or even if you need a hydraulic cylinder for a particular purpose you could think about talking to a specialist manufacturing company in Australia.